myplant REMOTE ENGINE OPERATION

Control your engine with just one click.

Control your engine with one click from anywhere, anytime, to the highest standards of security. Elevate your operational efficiency and engine management with our comprehensive solution that caters to the demands of the connected world.

Enhance your operational efficiency and profitability with our Remote Engine Operation (REO). It provides real-time insights into your engine’s performance, advanced remote-control capabilities and seamless integration with your existing infrastructure.

YOUR POWER. YOUR DATA. IN YOUR HANDS.

Take a closer look at how REO can support operational profit drivers. They include:

Proactive engine management – Reduce unexpected interruptions and enhance productivity through remote acknowledgment of engine alarms, ensuring smooth operations.

Enhanced engine availability – Boost your engine’s availability and reduce maintenance expenses with engine data monitoring and operational planning for continuous performance.

Lower operational costs – Save time and resources by swiftly identifying and resolving issues during outages with our real-time and historical engine data trends.

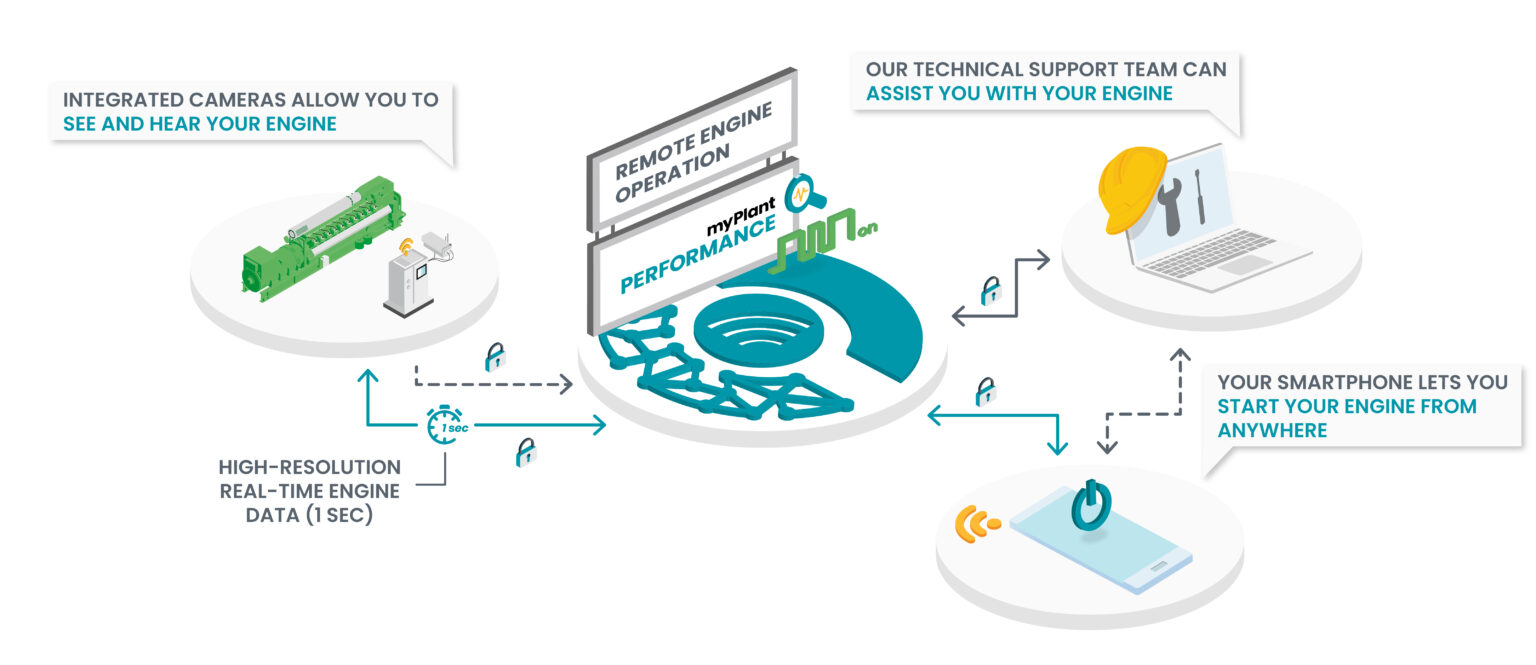

How does REO work?

Visual and audible engine interaction – Experience your engine in a new way: through a camera and a connectivity box, the digital tools that allow you to see and hear your engine’s performance, providing a high resolution and real-time data of its condition.

Remote engine assistance – Support your engine from remote: with the ability to diagnose and resolve your engine issues via remote alarm resets, you can ensure optimal performance and longevity of your assets, while simultaneously minimizing engine downtime.

Remote engine control – Achieve complete command over your engine: plan the start, stop, or adjust the desired output of your engine from any location, at any given time, using your device of choice, providing unparalleled convenience and flexibility.

Our Remote Engine Operation is the right tool that equips you with precise information and control over your industrial site or gas engine, no matter where you are.

Explore REO’s powerful features and see how.

Extensive remote engine control

- Start and stop your engine, and change its power setpoint

- Remotely acknowledge engine alarms through a safety-centered auditable workflow1

- Access real-time engine data trends, and live video stream from cameras on site2

- Plan in advance your engine operation (start, stop, desired power output)

Operation notifications

- Get notified about upcoming planned operations

- Stay informed about your engine’s current condition with real-time status updates, such as start, stop, trip, online, and offline.

Simple to use

- Define yourself which functionalities are key to you thanks to our fully customizable dashboards

- Be platform independent: no need to install any software on your laptop or smartphone. You can access Remote Engine Operation directly online, on any connected device

Easy integration

- Install easily on DIA.NE XT4, and on any DIA.NE XT3 equipped with an XT4 Winserver

- Monitor in REO the live stream of your engine in operation by connecting off-the-shelf cameras3

Transparent operation and reporting

- Keep an eye on your engine’s full history of remote operations through a convenient timeline view

- 1 second resolution engine data4

- Facilitate faster remote support from INNIO by sharing the same tools used by our technicians

2 flexible solutions tailored to your requirements

To enhance your experience… we are offering Remote Engine Operation for a variety of DIA.NE XT configurations. Whether you’re using DIA.NE XT, XT3 (with installed XT4 Winserver5), or DIA.NE XT4, we’ve got you covered.

With you in mind, we have integrated an optional hardware component, the myPlant Connectivity Box (myCoBo). This device unlocks additional app functionalities, making your remote engine operation smoother and more efficient.

Requirements

- Software update

- myCoBo installation

myCoBo-enabled features

- Access real time engine data and monitor your engine’s live stream operation from connected on-site cameras.

- 1 second resolution engine data

COMPLETE THE FORM TO GET STARTED WITH myplant TODAY

1 Requires dedicated user advanced training and is subject to the regulations defined in INNIO Jenbacher TA 1100-0111 on alarm acknowledgement.

2, 3 Check product technical instruction for compatibility

4 Might require technical validation, based on specific version of DIA.NE system

5 Older Winserver versions are not compatible with the system.