Trigeneration / CCHP

Combined cooling, heat, and power – CCHP.

Combined cooling, heat, and power systems, also known as CCHP power plants or trigeneration systems, are the combination of cogeneration plants and absorption chillers.

Our dedicated Jenbacher experts are available to provide personal consultation.

Jenbacher gas engines offer an excellent solution for generating air conditioning and/or refrigeration. Cogeneration equipment offers high efficiency and low emissions. Absorption chillers provide an economic and environmental alternative to conventional refrigeration with compression chillers. Combining those two elements enables excellent total fuel efficiency, elimination of HCFC/CFC refrigerants, and reduced air emissions.

How it works?

In a CCHP power plant, combining a cogeneration plant with an absorption refrigeration system enables the use of seasonal excess heat for cooling. Hot water from the cooling circuit of the cogeneration plant serves as drive energy for the absorption chiller.

- Absorption chillers produce chilled water by heating two substances (e.g., water and lithium bromide salt) that are in thermal equilibrium to separation, then reuniting them through heat removal.

- The heat input and removal, achieved in a vacuum at varying pressure conditions (approximately 8 mbar and approximately 70 mbar), brings the materials into imbalance, thereby forcing them to undergo desorption or absorption.

- Water (refrigerant) and lithium bromide salt (absorbent) are generally used for generation of chilled water in the temperature range from 6 to 12°C. Ammonia (refrigerant) and water (absorbent) are used for low temperature chilling down to -60°C.

Benefits of trigeneration

- Absorption-based systems for air conditioning are much more efficient and economical in producing low NOx emissions, compared to conventional refrigeration technology

- By operating with heat, trigeneration uses relatively inexpensive “excess energy”

- Produced electricity can be fed into the public grid or used to cover electricity requirements of the plant

- During cold seasons, heat can be used to cover heating requirements

- Simple, high-quality construction, with no moving parts, enables low maintenance expenses and long intervals between overhauls

- Operation is noiseless

- Dual fuel capability is available

- Operating and life-cycle costs are lower

- Using water as a refrigerant eliminates use of ozone-damaging substances

Experience our webinar: Learn about our CHP solutions

Jenbacher North American team invites you to review the recording of our recent webinar, to learn how Jenbacher can help you develop your power plant projects, including equipment design and performance, using hydrogen and much more! In the webinar, you will learn more about:

- Overview of an independent power plant and its components

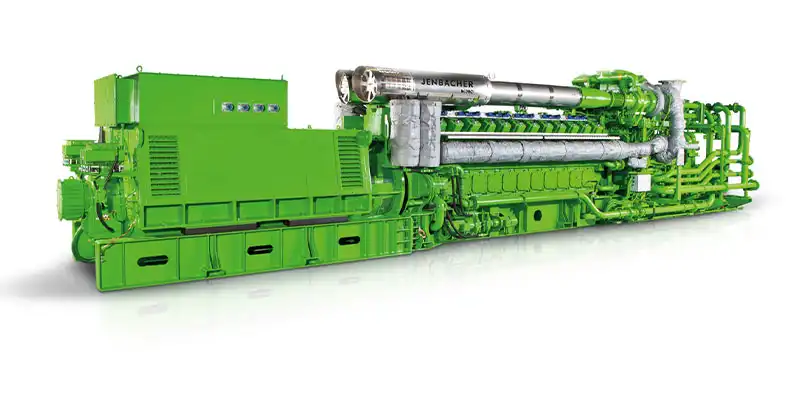

- Jenbacher’s highly efficient type 6 genset

- Our hydrogen power generation solutions

- How proven equipment design improves performance

- Power generation solutions with quick delivery and easy installation

The information provided is relevant for the North American market. Please reach out to our experts to discuss your project.

Selected Case Studies

Dettenhausen (GER)

thanks to a partnership between industry and municipal utilities

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

BOPP Barranquilla (COL)

Trigeneration solution for plastic industry

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Shanghai International Tourism and Resort Zone (CHN)

Location

Installed engines

Electrical output

Electrical efficiency

Total efficiency

Energy source

Commissioned

Huadian Industrial Park (CHN)

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Barts NHS Hospital (GBR)

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Changsha Happy City (CHN)

supports the energy transition in China

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Dettenhausen (GER)

thanks to a partnership between industry and municipal utilities

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

BOPP Barranquilla (COL)

Trigeneration solution for plastic industry

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Shanghai International Tourism and Resort Zone (CHN)

Location

Installed engines

Electrical output

Electrical efficiency

Total efficiency

Energy source

Commissioned

Huadian Industrial Park (CHN)

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Barts NHS Hospital (GBR)

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Changsha Happy City (CHN)

supports the energy transition in China

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Our experts are ready to help you!

Looking for onsite power solutions?

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid?

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let’s get started!

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.