Sewage Gas

Turning Wastewater into Green Energy.

You may operate a wastewater treatment plant (WWTP), be a decision-maker in environmental infrastructure projects, or be part of a business that generates large volumes of wastewater.

Our dedicated Jenbacher experts are available to provide personal consultation.

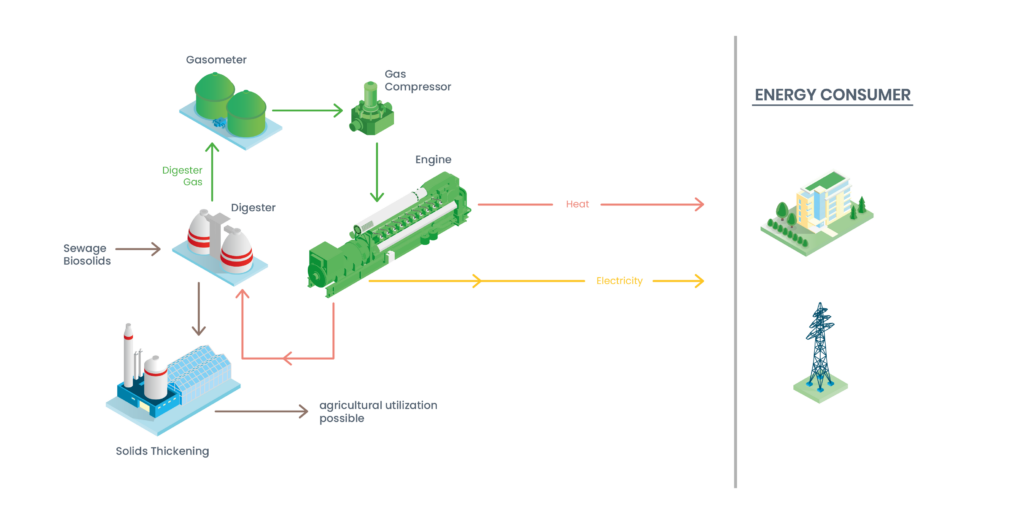

How does it work?

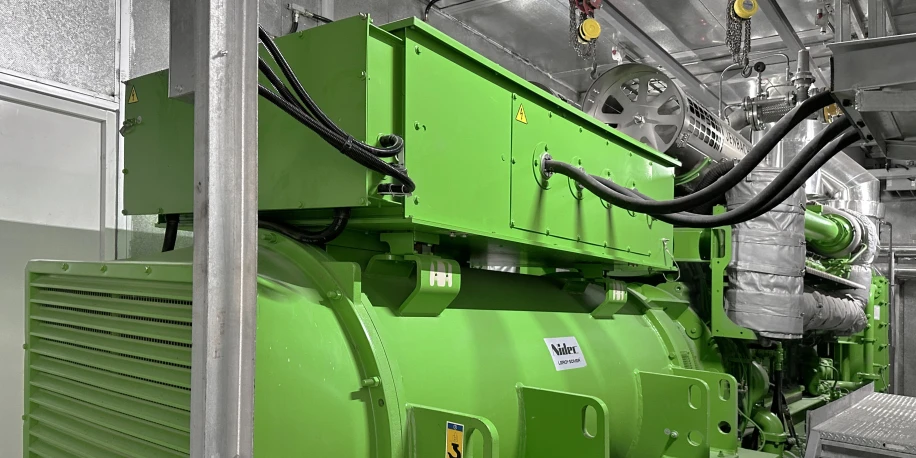

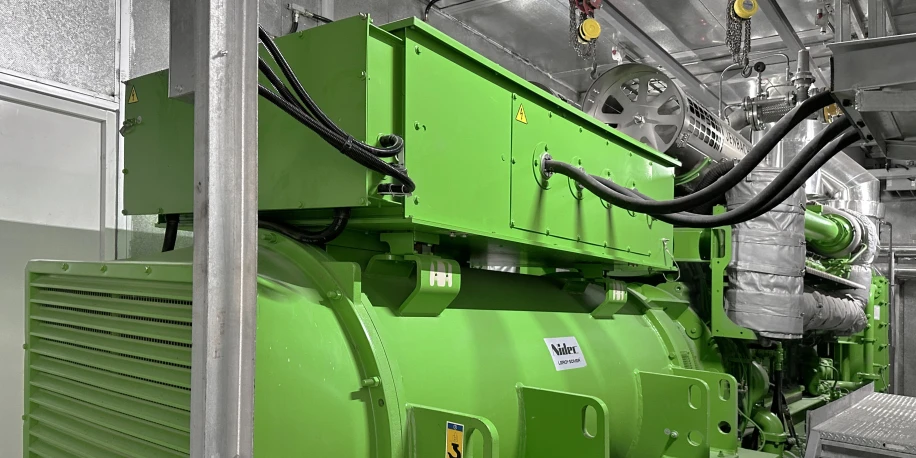

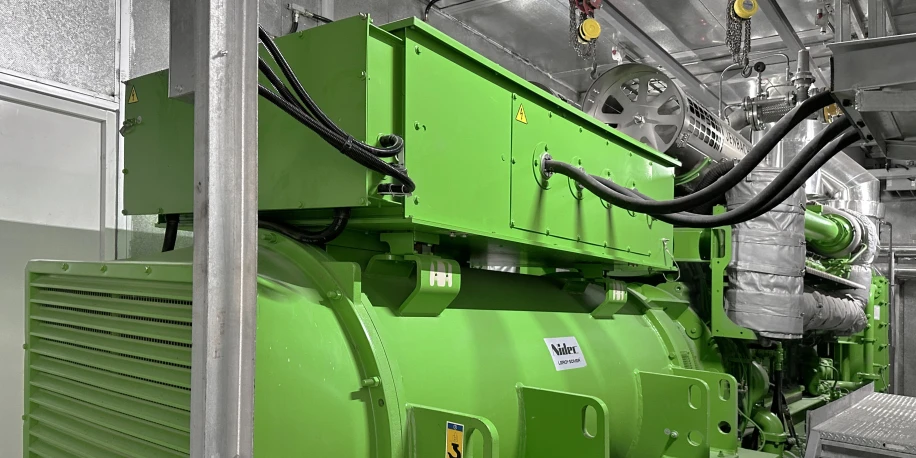

Jenbacher gas engines provide the solution to the rising energy costs that wastewater treatment plant (WWTP) operators have had to pay to meet their discharge permit requirements. Our gas engines efficiently and reliably convert sewage gas into electricity in plants that use anaerobic digestion for biosolids treatment. The process covers up to 80% of a plant’s electricity needs and makes it unnecessary to burn fossil fuels for heating. The gas produced in anaerobic digesters from municipal WWTPs generally contains 55 to 65% methane and typically has a low heating value of 500 to 600 BTU/SCF.

Impressive Potential and Results

On average, about one megawatt of electricity can be generated from biosolids for every 25-30 MGD of treated wastewater. Several active installations fueled by sewage gas show the generation potential of the INNIO solution.

- In Tirol, Austria, two Jenbacher gas engines, a J208 and a J312, power and heat a facility that provides 120% of its energy demand and sends the excess power to the local grid.

- Two J316 engines provide 1.7 MW of renewable energy for a facility in Portland, Oregon. The electrical output meets about 40% of the plant’s electricity demand.

- A cogeneration plant in Spain uses three Jenbacher J620 gas engines to produce 8 MW of power – more than four times the norm for a standard biogas plant.

- Three more J620 units enable a plant in Santiago Basin, Chile, to produce up to 60% of its power with renewable electricity.

Benefits of CHP for wastewater treatment plants

- LEANOX controls with turbo charger bypass help ensure the correct air-to-gas ratio to lessen exhaust gas emissions while maintaining stable engine operation.

- Electrical efficiency of up to 43% reduces the need to purchase energy from the public grid.

- A fully developed monitoring function, including remote monitoring, creates high levels of reliability.

- Maintenance intervals – 60,000 operating hours for major overhauls and 30,000 for cylinder heads – cut maintenance costs.

- Seamless dual fuel mixing evens out gas production fluctuations by supplementing natural gas as needed.

- High power engine density reduces space requirements and installation costs.

- The low-vibration engine has negligible impact on buildings.

Selected Case Studies

El Gabar Al Asfar Wastewater Treatment Plant (EGY)

boosts power and cuts costs at one of Egypt’s largest wastewater treatment facilities

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

CN Paper Mill (CHN)

Solution reduces costs while converting waste to energy

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

K&C Valley (IND)

Combined heat and power plant harnesses sewage gas to generate greener power in India

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Muddy Creek Wastewater Treatment Plant (USA)

helps wastewater treatment plant increase efficiency, reduce power costs, meet environmental compliance

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

El Gabar Al Asfar Wastewater Treatment Plant (EGY)

boosts power and cuts costs at one of Egypt’s largest wastewater treatment facilities

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

CN Paper Mill (CHN)

Solution reduces costs while converting waste to energy

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

K&C Valley (IND)

Combined heat and power plant harnesses sewage gas to generate greener power in India

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Muddy Creek Wastewater Treatment Plant (USA)

helps wastewater treatment plant increase efficiency, reduce power costs, meet environmental compliance

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Our experts are ready to help you!

Looking for onsite power solutions?

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid?

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let’s get started!

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.