Hydrogen

CO2-neutral power generation solutions

Jenbacher is ready for the age of hydrogen! With its potential as a CO2-free fuel source and its ability to be stored, hydrogen (H2) is an important part of the energy transition. Jenbacher already has 50 years of experience in converting alternative fuels into power—and more than 8,500 of our Jenbacher gas engines are operating on climate-neutral gases right now. Some of these engines have already been converted to hydrogen power engines, showcasing the versatility of our technology.

Our dedicated Jenbacher experts are available to provide personal consultation.

As you face stricter emission regulations and a push toward CO2-neutral power solutions, how will you reach a greener future? Renewable power is part of the answer, of course, but traditional technologies also can become CO2-free—if they use hydrogen (H2) as fuel. This is where our hydrogen gas power plant solutions come into play.

Well suited for engines for power, heat and/or cooling generation, H2 can be integrated with solar, wind, or other renewable technologies to form the backbone of your 100% renewable microgrid. When using green hydrogen in engines, you can even achieve a zero-carbon emission solution. This is made possible by our ability to convert gas engines to hydrogen, ensuring a seamless transition to a greener future.

INNIO Group’s Jenbacher products can deliver hydrogen-ready power plants today. With an investment in our Jenbacher hydrogen combined heat and power (CHP) technology, you can run your plant on conventional pipeline gas and flexibly start mixing in H2. The switch to a CO2-free operation can be done with an engine conversion when hydrogen becomes more readily available.

In 2020 the world’s first Jenbacher gas engine has been converted to run on hydrogen at HanseWerk Natur in Hamburg-Othmarschen, Germany, a prime example of how INNIO gas engines can be converted to use hydrogen as fuel. The Jenbacher gas engine in the 1 megawatt class supplies 30 residential units in a district heating network as well as a kindergarten, a sports field and a leisure center including a cinema.

To use Youtube, please give your consent to the creation of cookies used by this service.

3 ways to use hydrogen with Jenbacher engines

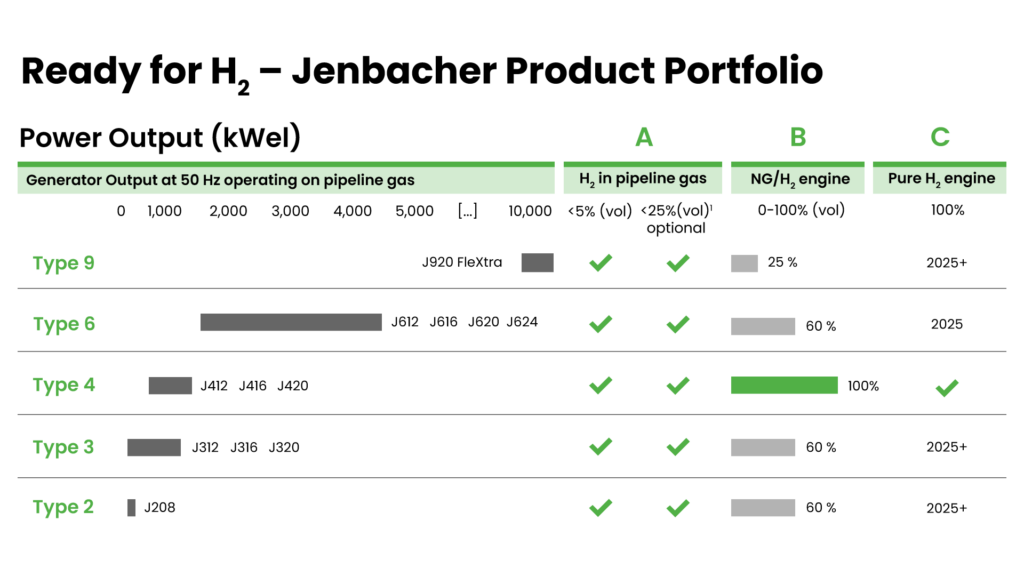

H2 in pipeline gas

All new Jenbacher engines are “Ready for H2“.* They can be offered with the option of running with up to 25% (vol) of hydrogen in pipeline gas. As hydrogen becomes more readily available, all “Ready for H2” units and most of the currently installed Jenbacher pipeline gas gas-fueled engines can be converted to operate on 100% hydrogen. Type 4 engine solutions are available to run on 100% H2 today.

* In general, “Ready for H2” Jenbacher units can be converted to operate on up to 100% hydrogen in the future. Details on the cost and timeline for a future conversion may vary and need to be clarified individually.

H2 locally admixed to conventional gas

Up to 60% (vol) hydrogen content can be admixed to pipeline gas fuel for use in special versions of Jenbacher Type 3, 4, and 6 engines. Type 4 engines and CHP systems are available today as dual gas-fuel solutions capable of running on 100% conventional gas, 100% H2, or mixtures of conventional gas and H2.

100% H2 as an energy source

Jenbacher Type 4 engine solutions now are available as 100% H2 engine systems operating exclusively on hydrogen. These plants are CO2-free by design.

Hydrogen Brochure

As a form of storable renewable energy, hydrogen is not only carbon-free, but also an important enabler in the energy transition. Using hydrogen in Jenbacher power plants has a whole raft of benefits. Download our hydrogen brochure for more detailed information.

Hydrogen-Powered Gensets for Electric Vehicle Charging: A Cost-Effective Pathway to Integrate Jenbacher Solutions in Sustainable E-mobility Infrastructure

This white paper provides a thorough analysis of the shift towards a robust e-mobility charging infrastructure. It explores the potential of pairing innovative energy storage solutions with INNIO Group’s Jenbacher gas engines to effectively manage charging demand.

Hydrogen-based Power Generation: A Net-Zero Backup Solution for Data Centers

Learn more in our white paper, how Jenbacher hydrogen generators can be used to decarbonize the backup power supply in data centers. It is intended to be used as a decision-making aid for the transformation path towards net-zero data centers.

Learn more about our Jenbacher data center solutions.

Hydrogen-based Power Generation: A Net-Zero Backup Solution for Green Ammonia Hubs

Learn more in our white paper on the use of hydrogen engines for decarbonizing the power supply of green ammonia hubs. By outlining the technoeconomic specifications of this technology in general and INNIO Group’s Jenbacher solutions in particular, the paper can be used to aid project developers and EPCs in their decision-making when selecting a suitable backup solution for their green ammonia production facilities.

The Jenbacher H2 capabilities—today and tomorrow

1 Conventional gas

2 Subject to required modifications for the certification of the fuel gas components. A modification of the maintenance schedule for such components may be required.

In general, “Ready for H2” Jenbacher units can be converted to operate on up to 100% hydrogen in the future. Details on the cost and timeline for a future conversion may vary and need to be clarified individually.

Hydrogen power plant solutions

We are offering upgrades for existing plants or installation of new ones. Whether you choose to convert your current Jenbacher engine plant to “Ready for H2” operation, accepting up to 25% (vol) of hydrogen in pipeline gas, or opt for one of our Type 4 100% H2 engines, you are making a smart investment choice. Combining the electrical energy of hydrogen with heat generation can significantly increase the overall efficiency of the hydrogen power plant solution.

Smart investment in hydrogen technologies

Some of the world’s largest economies—the US, Japan, European Union member countries, China and Canada, for example—have committed to large-scale investment in hydrogen technology in this decade with the belief that H2 will be widely available by 2030. By investing now in INNIO’s Jenbacher “Ready for H2” technology, you will be ready for a hydrogen-based economy. With Jenbacher H2 engines, you can quickly convert from pipeline gas to hydrogen and avoid stranded investments.

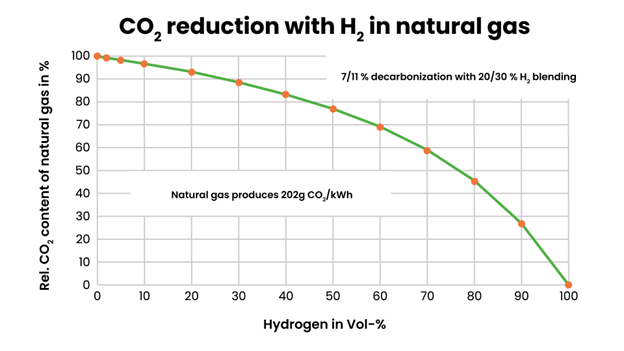

Carbon tax case and saving potential

A 1 MW CHP plant running on about 4,000 operating hours per year on conventional gas has current yearly emissions of about 2,500 tons of CO2. When operating with 100% H2, the same plant based on the current CO2 price of around 80 €/ton from the EU Emission Trading Systems (ETS) would save a total of €160,000 per year.

Tour of our 100% hydrogen Jenbacher container

Learn more about INNIO’s groundbreaking integrated Jenbacher solution designed for 100% hydrogen operation. Join Henning Liepelt on a detailed tour as we navigate the path to a sustainable, net-zero future. This tour will give you an insight into how we convert gas engines to hydrogen, making them a part of our hydrogen gas power plant solutions.

To use Youtube, please give your consent to the creation of cookies used by this service.

Learn more about our containerized solution here.

Benefits of hydrogen power generation

- Rely on proven technology

Build on proven and established engine technology that enables you to flexibly move to 100% H2 operation. Our upgrade can be done during an overhaul. - Flexibly move to sustainable energy

Although H2 is a rare energy source today, this will change over time. With your Jenbacher “Ready for H2” plant, you won’t lose momentum. You can move as fast as H2 availability progresses and harvest the green potential. - Meet future emission goals

Once your proven Jenbacher power plant is operating with 100% H2, you’ll have a CO2-free energy solution. - Improve resource efficiency

With CHP efficiency as high as 95%, about one-third of the H2 fuel can be saved versus power generation alone. And, by running our H2 technology in CHP mode, you can help drive the energy transition as you generate CO2-free heat. - Help ensure supply security

With their dispatchability, Jenbacher engines can help balance the intermittence of renewable energy sources such as wind and solar and help maintain the resilience of the electrical grid.

Experience our webinar: Learn about our CHP solutions

Jenbacher North American team invites you to review the recording of our recent webinar, to learn how Jenbacher can help you develop your power plant projects, including equipment design and performance, using hydrogen and much more! In the webinar, you will learn more about:

- Overview of an independent power plant and its components

- Jenbacher’s highly efficient type 6 genset

- Our hydrogen power generation solutions

- How proven equipment design improves performance

- Power generation solutions with quick delivery and easy installation

The information provided is relevant for the North American market. Please reach out to our experts to discuss your project.

Selected Case Studies

RAG Austria (AUT)

Harnessing the summer sun for winter energy using a Jenbacher hydrogen solution

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Coastal Power Plant Kiel

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Hyosung (KOR)

with Asia Pacific’s first 100% hydrogen engine power plant

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Hychico (ARG)

of global renewable energy with hydrogen

Location

Installed engines

Electrical output

Energy source

Commissioned

Hansewerk Natur (GER)

using Jenbacher technology

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

RAG Austria (AUT)

Harnessing the summer sun for winter energy using a Jenbacher hydrogen solution

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Coastal Power Plant Kiel

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Hyosung (KOR)

with Asia Pacific’s first 100% hydrogen engine power plant

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Hychico (ARG)

of global renewable energy with hydrogen

Location

Installed engines

Electrical output

Energy source

Commissioned

Hansewerk Natur (GER)

using Jenbacher technology

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Our experts are ready to help you!

Looking for onsite power solutions?

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid?

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let’s get started!

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.