Biogas

Turning biogas into heat and power.

Instead of producing waste that creates emissions, organic waste—also called biomass—can be used as a valuable energy source when turned into biogas.

Our dedicated Jenbacher experts are available to provide personal consultation.

These days everyone is talking about sustainable energy, but actions speak louder than words. Using biogas from the fermentation of organic waste, Jenbacher biogas engines can create heat and power as a reliable energy source to power your business today, tomorrow, and in the future.

Your Challenge

With the phase-out of coal and nuclear power, centralized electricity producers often are replacing larger plants with a number of smaller, decentralized wind energy and photo-voltaic plants that provide power and heat where it is needed. There’s a downside, though: fluctuations in electricity production due to volatility of renewable energy sources. To avoid blackouts, the missing electricity must be generated through other available sources, quickly. That’s where another renewable energy source, biogas, comes into play—as a complement to these volatile, weather-dependent energy sources.

Industry Trends

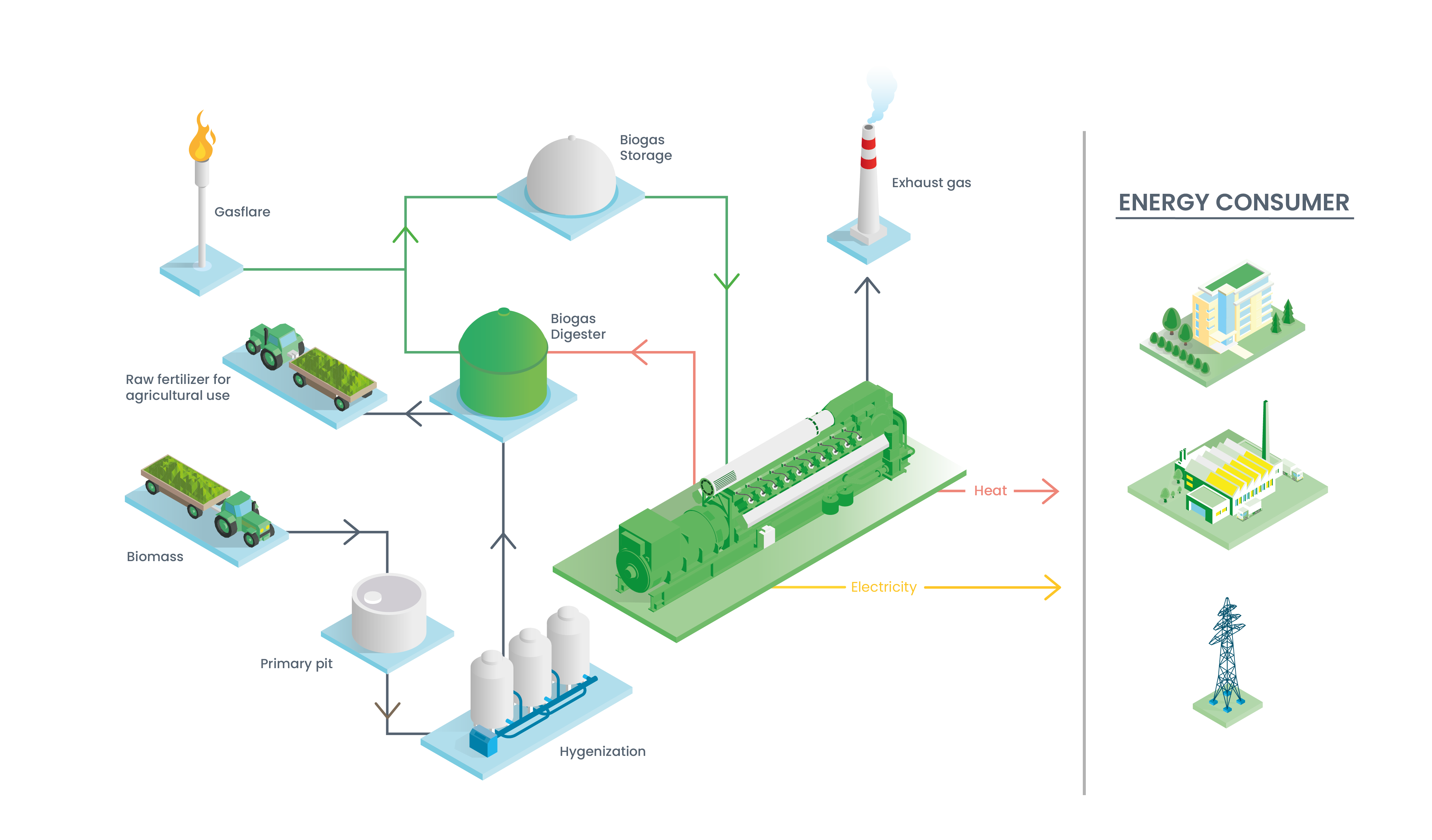

Instead of producing waste that creates emissions, organic waste—also called biomass—can be used as a valuable energy source when turned into biogas. And the use of biogas to fuel engines as a substitute for fossil fuels is on the rise across the energy market. That’s because this renewable energy source complements other renewable energy sources such as wind and solar–with one big difference. It’s not dependent on the weather!

Our Approach

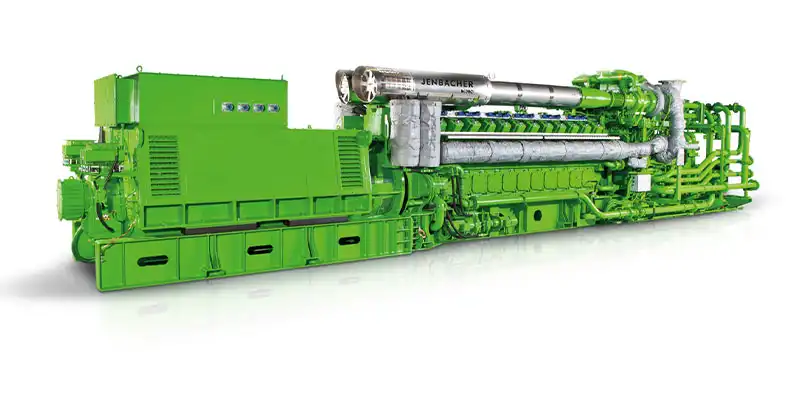

Jenbacher offers flexible, innovative, and proven combined heat and power (CHP) biogas solutions that turn biogas produced from biomass into power and heat. With a wealth of experience in biogas applications, Jenbacher also is a global technology leader when it comes to engine-based power generation and waste heat recovery solutions including biogas CHP.

The Jenbacher solution

Jenbacher biogas generator sets are widely used by farmers and industrial users across the globe. Onsite biogas cogeneration plants can be used by businesses to supply their own electricity and heat needs, or biogas gensets can transform biogas to electricity for future off-take to the grid.

Biogas CHP generators can be installed inside buildings or also can be supplied as ready-to-use biogas-to-power containerized solutions that can be used in various applications, for example, as a part of a biomass energy power plant.

The process of biogas generation is divided into three steps: Preparation of the bio-input, fermentation, and post-treatment of the residual material. At the start, the organic material is collected in a primary pit, sterilized to remove harmful germs in case of food waste and moved to the digester. The biogas produced in the digester is collected in a gas storage tank to ensure a continuous supply of gas, independent of fluctuations in the gas production. Finally, to turn biogas into electricity, it is fed into a biogas engine.

Once the fuel is fed into the biogas cogeneration plant, it sets the engine into action. This engine drives a generator that turns biogas into electricity. The heat produced during this process, which would otherwise be wasted, is captured and used for heating applications. This dual use of energy makes the biogas cogeneration plant highly efficient, enabling it to reach total efficiency levels of up to 90%. With Jenbacher biogas CHP generators, the process is not only efficient but also sustainable.

Benefits of biogas engines

An investment in INNIO’s Jenbacher biogas cogeneration plants let you realize impressive economic and ecological benefits when using biogas for power generation:

- Highly efficient for combined onsite power and heat generation with biogas (biogas CHP).

- Ready-to-use biogas power plant solutions in containers.

- A green waste-to-energy/waste-to-power application decreases your business’ carbon footprint.

- An alternative disposal of dung, liquid manure and biowaste, while simultaneously harnessing energy—a valuable substitute for conventional fuels.

A proven concept

Jenbacher has delivered more than 6,000 biogas engines that can generate a total electrical output of green energy of approximately 5.5 GW. Our delivered biogas-fueled fleet has the potential of an annual production of 44 TWh of electricity. This amount of energy can deliver annual average electricity for around 11.7 million EU homes.

GLOBAL BIOGAS BROCHURE

Download our “Waste to power” biogas brochure for more detailed information.

BIOGAS SOLUTIONS FOR SOUTHEAST ASIA

Download our Southeast Asia biogas brochure for more detailed information.

HESLERHOF, BIOGAS PLANT IN GERMANY

With the installation of a Jenbacher J420 engine and investments into a large buffer storage tank and a gas storage tank, the biogas plant at the Heslerhof Farm in Germany was converted into a renewable storage power plant with flexible, power market-driven operation.

ORGANIC WASTE TREATMENT CENTER IN CHINA

The first kitchen waste-to-biogas power project in China’s Anhui Province is turning 800 tons per day of catering and kitchen waste into renewable power, resolving Hefei City’s kitchen waste disposal challenge while emitting 7,900 fewer tons of CO2.

Selected Case Studies

Biohof Querdel (GER)

A contribution to the energy transition in Germany

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Agrotor (HND)

uses waste byproduct for power generation

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Biotown (USA)

to power and heat from RNG/biomethane

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Klostermansfeld (GER)

for regional renewables

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Del Monte (PHL)

Jenbacher engines power 1 st combined heat and power plant to run on biogas in the Philippines

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Memmingen Airport (GER)

to achieve a climate-neutral airport

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Biohof Querdel (GER)

A contribution to the energy transition in Germany

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Agrotor (HND)

uses waste byproduct for power generation

Location

Installed engines

Electrical output

Total efficiency

Energy source

Commissioned

Biotown (USA)

to power and heat from RNG/biomethane

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Klostermansfeld (GER)

for regional renewables

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Del Monte (PHL)

Jenbacher engines power 1 st combined heat and power plant to run on biogas in the Philippines

Location

Installed engines

Electrical output

Thermal output

Total efficiency

Energy source

Commissioned

Memmingen Airport (GER)

to achieve a climate-neutral airport

Location

Installed engines

Electrical output

Thermal output

Energy source

Commissioned

Our experts are ready to help you!

Looking for onsite power solutions?

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid?

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let’s get started!

Resources & Downloads

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.