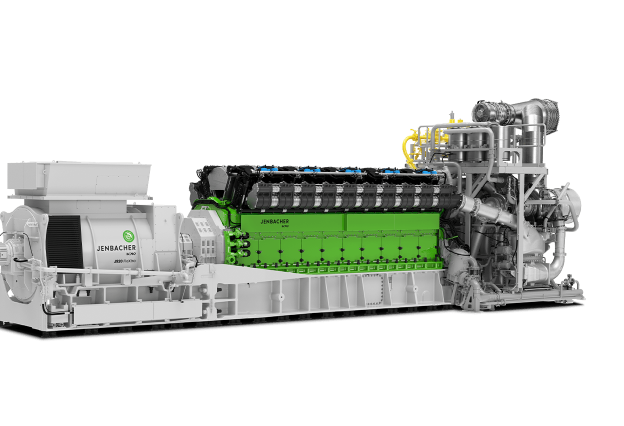

Jenbacher Type 9: J920 FleXtra

Whether you’re seeking full power at high efficiency levels or a 10MW unit capable of start-up in 2 minutes, the Jenbacher J920 FleXtra engine is a reliable solution for large gas engine power generation plants.

This Jenbacher engine is designed to support a broad variety of multiple-engine power plant solutions–from remote power supply to combined heat and power (CHP) generation.

Scope of supply:

50 Hz

60 Hz

Jenbacher can change the technical data unilaterally. In the case of such change, we will update the data on our pages as soon as we can.

Please reach out to our experts to get help with engines selection, obtain the technical parameters for your gas composition.

Output and efficiency at generator terminals. Energy input is according to DIN ISO 3046 and DIN 6271, respectively, with a tolerance of + 5%.

All data according to full load and subject to technical development and modification.

Based on emission values of 250 and 500 mg/Nm3 NOx at 5% O2 at dry exhaust gas.

Base for biogas and sewage gas versions: 65% CH4 / 35% CO2.

Base for landfill gas version: 55% CH4 / 40% CO2 / Rest N2.

Jenbacher J920 FleXtra Overview

The newest and largest Jenbacher engine has, at 48.7 percent, the highest electrical efficiency of any Jenbacher engine.

- A smaller carbon footprint and more energy efficiency.

- High power density at low investment costs.

- Stable power output and reliable efficiency in any ambient condition.

- Quick startup for grid stabilization and easy maintainability.

J920 Features

INNIO’s J920 FleXtra Jenbacher engine is designed for durability, simple installation, and maintainability. The GenSet consists of three modules, including a generator, engine, and a turbocharger module, providing a high quality, pre-fabricated, standardized generator-set module. Each module is factory-tested, then shipped separately and assembled onsite, offering reduced installation time. In addition, the modules have highly standardized interfaces that work well with balance of plant (BOP) systems, and ultimately simplify BOP installations and total plant erection time. To maximize plant availability, the J920 FleXtra is optimized for operation and maintainability in the following ways:

|

POWER UNIT The J920 FleXtra power unit concept ensures low maintenance downtime as the complete power unit consisting of cylinder head, water jacket, cylinder liner, piston and con-rod can be exchanged with one assembly. |

FAST LOAD AND FAST TRANSIENTS With the Jenbacher J920, 10.4 MW of electric power can be provided from the start in 2 minutes. Newest model-based control technology ensures low engine-out emissions levels during the engine start and operation. Together with integrated after-treatment systems and controls overall NOx emissions are minimized over the full load range and even during fast transient operations. |

DIVIDED CAMSHAFT The J920 FleXtra is equipped with a segmented camshaft to support fast maintenance of individual segments through a service window at the top of the crankcase instead of disassembly of the whole camshaft. |

J920 Services: from start to finish

Planning

Based on our modular plant concept and your specific requirements, our highly experienced system engineers guide you through every critical planning phase (including the feasibility study, power plant engineering, and design) to tailor the best solution for your plant.

Plant Realization

INNIO's trained project and system engineers offer project management expertise to support you during the plant realization phases. Construction and commissioning procedures are standardized to minimize risks and assure a successful implementation. As part of our construction and plant installation services, INNIO provides worldwide engineering and procurement, and construction support through its qualified EPC-network. Our start-up and commissioning service also includes a series of tests performed by our experienced service technicians to ensure the optimum installation and functionality of the J920 gas engine in your plant.

Operation

Our contractual service agreements are designed to provide flexible and optimum care for your plant during operation. Through our global service network, you’ll have dedicated personnel that help ensure predictable operating costs of the Jenbacher J920 and risk mitigation. Remote diagnostics provide you with online access to your plant and J920 FleXtra equipment, thereby minimizing downtime, increasing plant availability, and lowering expenses for corrective maintenance. All work on your J920 FleXtra gas engine system — including upgrade, repair, and overhaul — is performed at your plant, saving you time and updating your engine with the latest technology.

Balance of Plant (BOP)

The right auxiliary equipment is of critical importance in ensuring that a power solution is economically feasible and provides your business with reliability, availability, and efficiency. Click on the provided BOP options to learn more.

Reach out to our experts to select the configuration that fits your business’ needs.

Available BOP elements may vary, depending on the engine and application type.

2-stage technology

The 2-stage turbocharger design of the J920 Flextra allows for no deration at higher altitudes and higher cooling water temperatures-perfect for hot ambient conditions.

Modular design for flexibility

Modular gas engine design allows for seamless installation with any multiple-engine configuration and offers flexible size options.

Superior total efficiency

Operating a Jenbacher J920 FleXtra at about 94% of total efficiency and 48.7% of electrical efficiency.

Scope of supply:

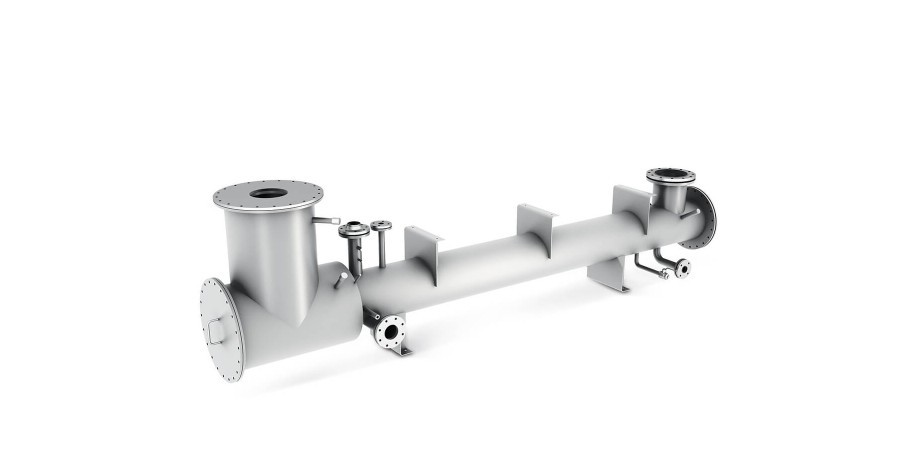

Combined Heat and Power Module (CHP Module) J920 FleXtra solutions allow customers to generate power and heat simultaneously at a very high total efficiencies, of about 94%.

The simple use of jacket water heat and heat from oil and charge air coolers, combined with heat from the gas engine exhaust makes CHP in combination with the J920 FleXtra gas engine a favorable solution. When the heating water circle is designed to include return water at 70°C and hot water at 90°C or more a high total efficiency is achieved. The 2-stage turbocharging technology has the ability to increase the total efficiency for providing power and heat up to the level of around 94%.

CHP Modules can generate hot water or steam at various parameters and can be integrated with your existing heat infrastructure. You can select the option that fits your project’s needs among the various heat recovery schemes provided by Jenbacher.

The scope of supply can be extended further with various balance of plant options (BOP) offered by Jenbacher, reach out to our specialists for help in selecting scope of supply and BOP options to fulfill your project’s needs.

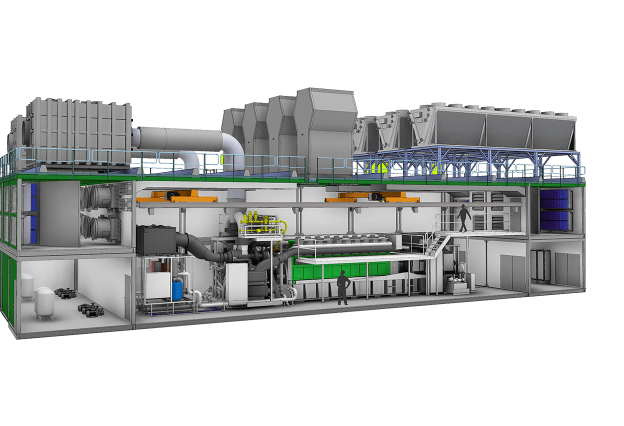

J920 FleXtra solution inside a powerhouse:

INNIO’s J920 FleXtra is specially adapted to large gas engine power plants. It offers a highly standardized powerhouse plant concept with fast delivery times and low installation costs. While the size of the plant, actual plant design, and layout depend on your specific customer needs and site requirements, the J920 FleXtra plant solution is developed as a modular system with a minimal footprint. This design allows for seamless installation with any multiple-engine configuration, and, therefore, offers flexible size options for a multiple 10 MW system at constant high electrical efficiency levels. Combining the multiple-engine concept with a 2-minute engine start-up time provides flexible power – from baseload to cyclic and peak operations.

Customer-only Resources

Get access to almost 2,000 Resources (such as Drawings, Service Technician Instructions, User Manuals, & more…) for Jenbacher Gas Engines with our dedicated Portal which includes advanced (yet easy to use!) search capabilities to find what you’re looking for.

Subscribe to our monthly Services Newsletter and additional materials to stay up-to-date with the latest Jenbacher technical news.

Type 9 Case studies

Our Services

Jenbacher Services

Bringing proven outcomes across the life cycle of your gas engines means less unplanned downtime, greater workforce efficiency, and lower operating costs. From commissioning to overhauling, our global network of qualified service experts provides the support you need, when you need it, by providing the latest technology.

Remote Monitoring & Optimization

Discover how partnering with digital technology can make your business life easier.

Jenbacher myPlant Performance Solution

Our cloudbased technology lets you manage your assets wherever you are, secure and live. Take control of the operating performance and profitability of your gas engine by giving it a digital life.