Remanufacturing

Services that matter

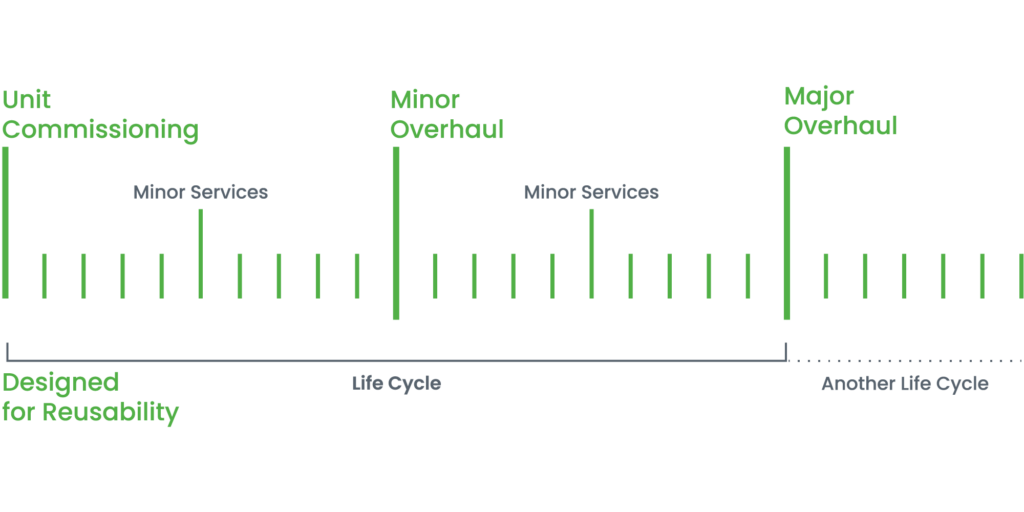

Driving circularity: The energy industry is increasingly dominated by the need for viable economic solutions that efficiently and sustainably use resources. That is why our products are designed to go through multiple life cycles. Based on your business model and service profile, our Jenbacher technicians can give your assets another life. With more than 1.2 million hours of skilled workers’ remanufacturing experience, INNIO Group – your Jenbacher system’s original equipment manufacturer (OEM) – partners with you to provide the remanufacturing solution you need.

Interested? We’ll connect with you. For optimal performance, Jenbacher Services has your power plant covered.

Why the OEM?

Seamless transition

Your OEM Remanufacturing advantages

Reduced environmental footprint and circularity, with re-used resources whenever possible

High reliability and lower costs, with our high-quality reUp components

Product upgrades that bring your equipment to top performance levels

Our portfolio

Tailored multiple life options

reUp engines

The engine is the heart of your power plant, and efficient engine performance allows you to operate with confidence. Choose from three different engine overhaul options for your engine’s next powerful life cycle.

reUp spare parts

An engine is only as good as the parts inside it. Choose from our reUp spare parts portfolio to support your ongoing maintenance planning.

With our support, your plant can operate for another life cycle

Our process

Disassembly & Cleaning

Engines and parts are disassembled and cleaned by skilled personnel to eliminate and remove elements that can hide flaws.

Inspection

All engines and parts are carefully inspected and thoroughly tested. We use OEM dimensions and tolerances to ensure specifications are met.

Machine & Assembly

Skilled assemblers follow exact standards and specifications from the most current engineering drawings when remanufacturing parts. All worn parts that do not meet our strict requirements are replaced by new OEM parts.

Testing

Every engine and part that leaves the factory has been comprehensively checked. Each test is recorded and stored electronically to maintain quality control.

Painting, Packing, & Shipping

Engines and parts are painted or preserved and carefully packaged to ensure they are protected from the elements. They can be installed right out of the box.

Case Studies

Starting a full new life with a version upgrade

"Our past experience of Jenbacher upgrades was so positive that it was an easy decision for us to upgrade to the next generation of the Jenbacher Type 3F. Thanks to the improved fuel usage of the modern 3F generation engine, we have been able to both increase our profitability and reduce our environmental footprint."

Thomas Roth, Head of Power and Engineering for Dominikus-Ringeisen-Werk (DRW), Bavaria, Germany

Starting a full new life with a version upgrade

"Our past experience of Jenbacher upgrades was so positive that it was an easy decision for us to upgrade to the next generation of the Jenbacher Type 3F. Thanks to the improved fuel usage of the modern 3F generation engine, we have been able to both increase our profitability and reduce our environmental footprint."

Thomas Roth, Head of Power and Engineering for Dominikus-Ringeisen-Werk (DRW), Bavaria, Germany

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether you are looking to address your basic service needs – from maintenance requests to day-to-day spare part and consumable requirements – to technical training for your workforce, digital solutions, or even system development plans, our Jenbacher Services experts can advise you on the solution that will be right for you.