Flare Gas

Hello useful energy.

For a long time, oil producers have simply flared associated petroleum gas (so called “flare gas”), considered an unwanted oil by-product. But with increased energy demand coinciding with an escalation in environmental consciousness — flaring now often is avoided, and sometimes even prohibited.

Our dedicated Jenbacher experts are available to provide personal consultation.

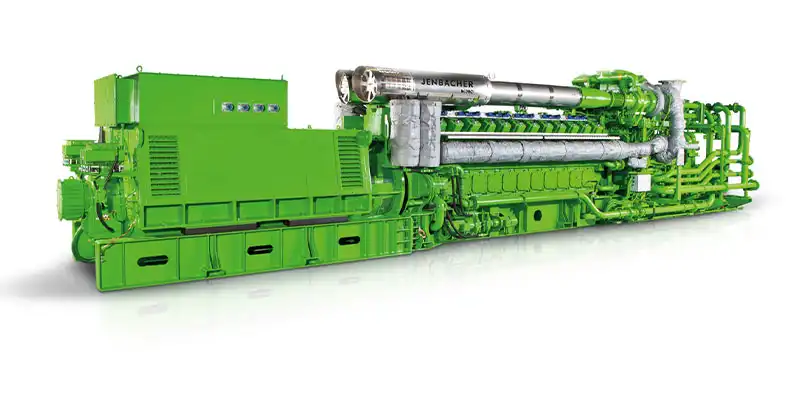

Backed by more than a century of innovation and engine-building experience, INNIO’s Jenbacher gas engines are ideally suited to deliver reliable and efficient performance for a variety of mobile and stationary applications – whether running on oilfield gas pulled straight from the ground, trucked-in liquid natural gas (LNG) or compressed natural gas (CNG).

How it works?

The field gas that is uncovered as the result of oil extraction is often wastefully flared or captured at significant expense. INNIO’s fuel-flexible gas engines offer an alternative solution that turns the field gas directly into power for applications such as drill rigs, artificial lifts, pump-jacks, and worker camps.

Rich-burn technology: Ideal for use in the most rugged environments, INNIO’s Waukesha EPA-certified gas engines employ a rich-burn combustion technology for precise control of the air-fuel ratio at stoichiometric conditions.

Low emissions: With the help of a three-way catalyst, rich burn engines can achieve very low exhaust gas emissions (such as NOx, CO, and THC) compared to lean burn engines.

Proven reliability: Rich-burn engines offer the same reliable, continuous performance proven in gas compression applications for a variety of field environments, including: hot fuel applications, greater than 50% load step capability, and extended service intervals.

High-altitude performance: While turbocharged diesel engines typically require derating above 1,500 feet (457 m), rich-burn technology offers increased flexibility with full power at altitudes up to 8,000 feet (2,438 m).

Fuel flexibility: Because rich-burn engines operate with a wide knock and misfire margin, they will run at higher loads on a variety of lower quality fuels..

Lean-burn technology: For drill rig applications running LNG, INNIO’s Jenbacher EPA-certified gas engines offer high-efficiency lean-burn control that is particularly well-suited to mobile oilfield applications.

Benefits of flare gas power generation

- Rugged, durable operation. Suited for reliable operation in harsh, remote, mobile or stationary mission-critical applications

- “Plug and Play” installation. Easily exchanged with existing diesel rig power generation drivers

- Reduced operational costs. Field gas operation cuts operational costs by up to 80% compared to diesel or dual-fuel operation

- Fuel flexibility. Ability to operate on a wide range of gas fuel quality, including high-BTU field gas (up to 1654 BTU HHV), HD-5 propane, and ethane, without knock

- Lower emissions. Paired with a three-way catalyst, rich-burn engines can attain or surpass the latest environmental requirements, producing emissions as much as 95% lower than diesel operation

- High-altitude performance. Maintains performance ratings at much higher altitudes (up to 8,000 feet) – without derate – compared to diesel technology

- Excellent transient load capability. Rich-burn engines handle large load variations in just two steps (nearly as well as diesel engines)

Resources & Downloads

La Cira (COL)

for lower energy costs, greater reliability, and reduced emissions

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

La Cira (COL)

for lower energy costs, greater reliability, and reduced emissions

Location

Installed engines

Electrical output

Electrical efficiency

Energy source

Commissioned

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.