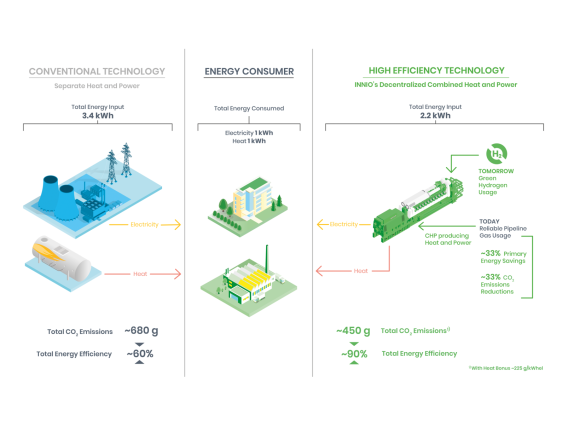

Cogeneration or combined heat and power solutions from Jenbacher are designed to generate both heat and power increasing overall power plant efficiency up to 90% and even more.

Cogeneration systems produce dependable electricity, heat and/or cooling from a single energy source while reducing fuel input by approximately 30% compared to the separate generation of electricity and thermal energy. Add in the fact that building energy systems at or near the point of use helps alleviate supply and distribution losses while providing a high degree of supply security and grid independency.

-

Your Challenge

You are under pressure. Your processes require significant electrical and thermal energy, but you face rising energy costs and a more vulnerable grid, driven by globally growing power demand. At the same time, environmental mandates to save energy and reduce emissions are more important than ever, and you are increasingly evaluated by the carbon footprint of your produced goods.

-

Industry Trends

Electricity often is procured from the public grid or from an energy provider. Thermal energy is converted from other energy sources at production facilities or procured from utilities. One way to address the current challenges and increase energy supply security is to contract with the public energy provider in combination with a backup power installation. Another trend in the industrial and consumer world is to use decentralized onsite power generation equipment to obtain higher supply security and grid independence. One of the most efficient ways to do so is with combined heat and power (CHP) as well as combined cooling, heat and power (CCHP) plants.

-

Our Approach

Jenbacher offers flexible and innovative Jenbacher CHP (cogeneration) and CCHP (trigeneration) power plant solutions. With a wealth of experience, Jenbacher is among the global technology leaders when it comes to engine-based power generation and waste heat recovery solutions.

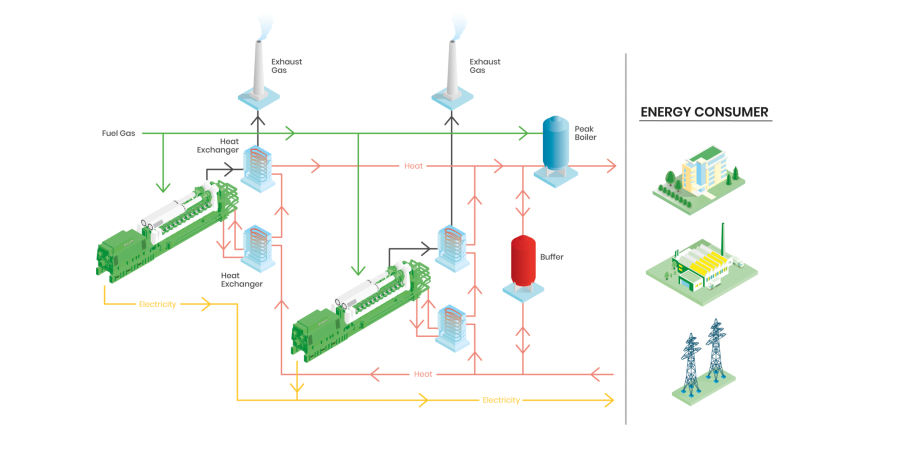

In addition to providing power for your local site, CHP also can be used to export generated electricity to the public grid, opening up additional value streams for you while supporting the local grid as needed. Similarly, you can use the generated thermal energy to satisfy your onsite thermal loads by creating hot water, hot air, steam or process heat. Thermal energy also can be stored for later or used for trigeneration to meet your air conditioning or refrigeration demands.

The Jenbacher solution

Tailored to your specific industrial operation.

A Jenbacher cogeneration plant consists of the power generation unit with an engine and a generator along with heat exchangers to take advantage of the heat resulting from the combustion process. The energy systems use all related heat sources such as the engine cooling water, lubricating oil, the air/fuel gas mixture and the exhaust gas. Water temperature levels of 100°C and more can be achieved, making Jenbacher CHP and CCHP solutions highly flexible.

Benefits of CHP

- Lower your energy costs and emissions

With up to 95% total efficiency, CHP solutions can reduce your energy consumption and CO2 emissions by more than 30% compared to the separate generation of an equivalent amount of power and heat. - Operate economically

CHP combined with heat storage allows you to operate your asset flexibly and optimize energy cost savings. - Increase resilience

During natural or manmade disasters, CHP systems can support your critical facility operations or stem potential losses sustained by your facility when the local or regional electric grid fails. - Make a sustainable investment

While many CHP systems run on pipeline gas, Jenbacher products can harness a wide variety of renewable and special customer generated gases - Open up the opportunity of CO2-free operation

Today’s Jenbacher engines with our Ready for H2 option can use up to 20% (vol) of H2 blended into the gas pipeline.

Our experts are ready to help you!

Looking for onsite power solutions?

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid?

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let's get started!

Selected Case Studies

Resources & Downloads

CHP Residential areas & municipalities

Language: English

Category: Brochures

CHP Residential areas & municipalities BrochureJenbacher Webinars – Designing Your Power Plant (2022)

Language: English

Category: Webinars

Jenbacher Webinars – Designing Your Power Plant JBCOM

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.