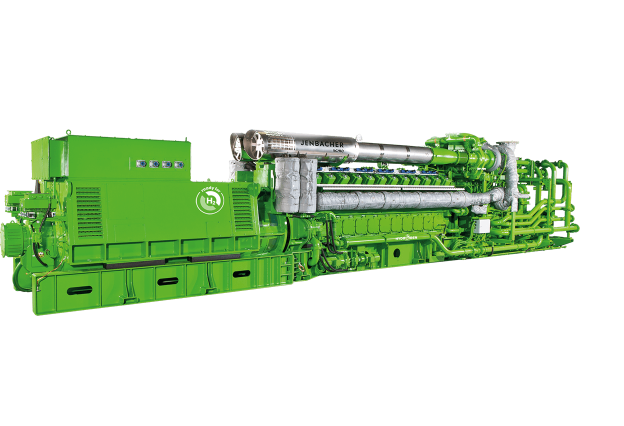

Jenbacher J624

A two-stage turbocharged V24-cylinder engine delivering outstanding power generation. The biggest engine in Type 6 family with the highest power output and efficiency.

A great choice for big size industrial, commercial and municipal applications.

Scope of supply:

50 Hz

60 Hz

Jenbacher can change the technical data unilaterally. In the case of such change, we will update the data on our pages as soon as we can.

Please reach out to our experts to get help with engines selection, obtain the technical parameters for your gas composition.

Output and efficiency at generator terminals. Energy input is according to DIN ISO 3046 and DIN 6271, respectively, with a tolerance of + 5%.

All data according to full load and subject to technical development and modification.

Based on emission values of 250 and 500 mg/Nm3 NOx at 5% O2 at dry exhaust gas.

Base for biogas and sewage gas versions: 65% CH4 / 35% CO2.

Base for landfill gas version: 55% CH4 / 40% CO2 / Rest N2.

Electrical Output4,459 kW

Thermal Output3,771 - 4,706 kW

Voltage480V - 13.8kV

Electrical Efficiencyup to 46.6 %

Thermal Efficiencyup to 46.8 %

L: 570 x W: 100 x H: 120 inches

Type 6 engines are loaded with features that enhance heat recovery, assure stable combustion, reduce emissions, and increase efficiency—taking the Jenbacher line to new levels of performance.

- A centrally-located purged pre-combustion chamber helps provide optimal ignition conditions.

- The spark plug ignition energy is amplified in the pre-combustion chamber, facilitating stable and reliable combustion.

- Miller valve timing creates reduced compression temperature and an increased safety margin to knocking limits, providing improved ignition timing and high efficiency.

All types of load profiles are supported – peaking, mid-merit and base load applications.

Scope of supply:

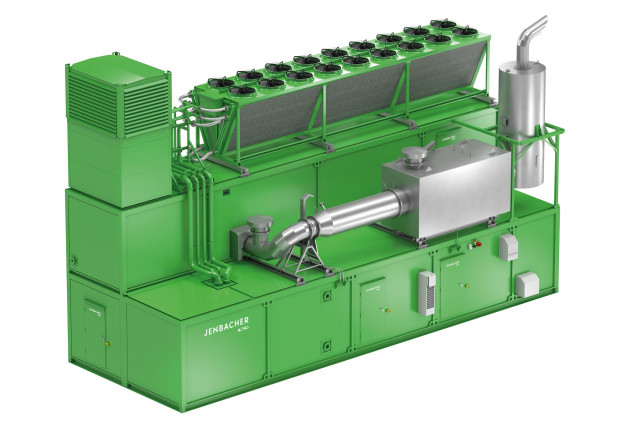

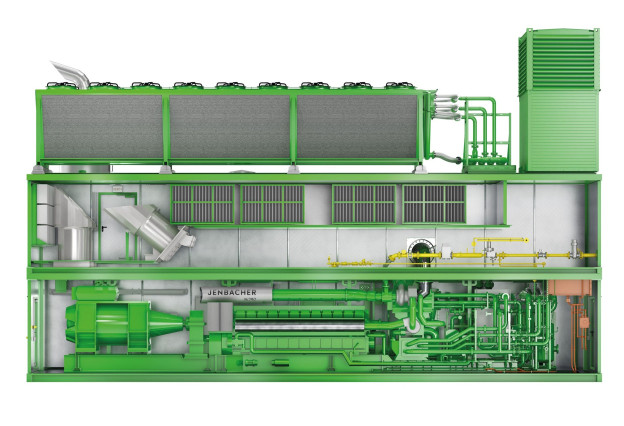

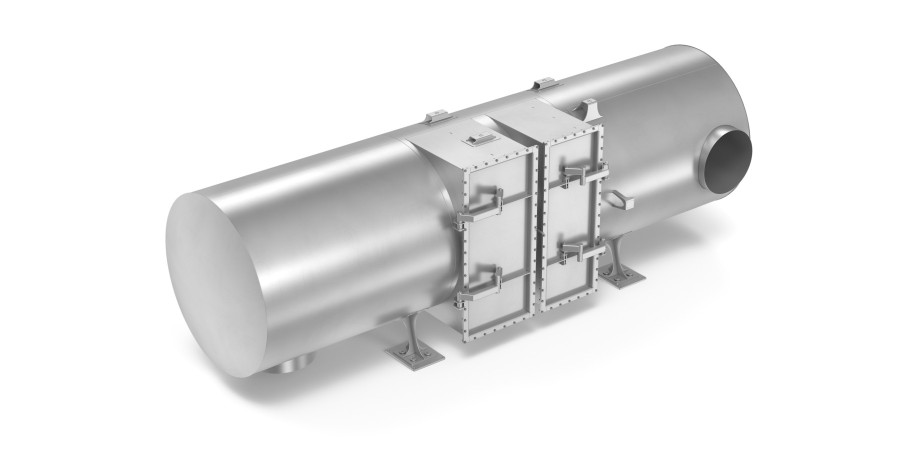

Combined Heat and Power Module (CHP Module) solutions allow customers to generate power and heat simultaneously at a very high total efficiencies, reaching 90% and even more.

Usual scope of supply:

- Engine and alternator installed on the frame

- Control panel, gas train

- Heat exchangers including exhaust gas heat exchanger

CHP Modules can generate hot water or steam at various parameters and can be integrated with your existing heat infrastructure. You can select the option that fits your project’s needs among the various heat recovery schemes provided by Jenbacher.

The scope of supply can be extended further with various balance of plant options (BOP), reach out to our specialists for help in selecting scope of supply and BOP options to fulfill your project’s needs.

CHP Modules can be installed inside a building or inside a container. To see more details about Jenbacher’s containerized solutions, click here.

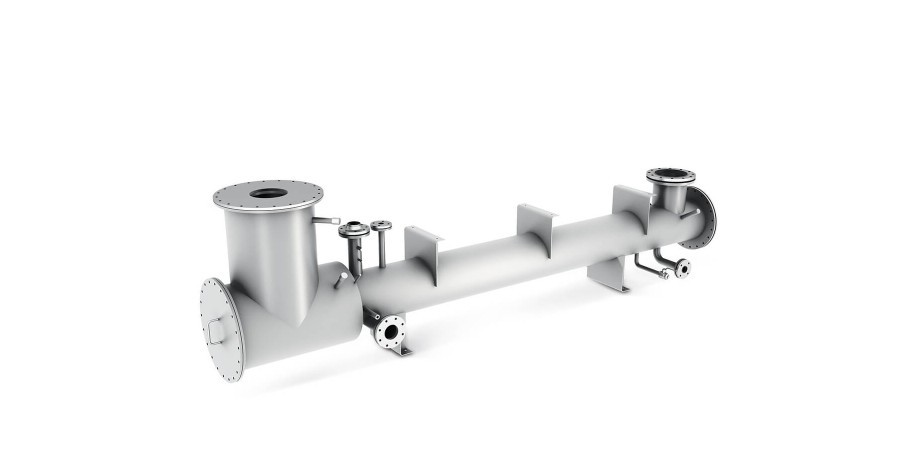

Balance of Plant (BOP)

The right auxiliary equipment is of critical importance in ensuring that a power solution is economically feasible and provides your business with reliability, availability, and efficiency. Click on the provided BOP options to learn more.

Reach out to our experts to select the configuration that fits your business’ needs.

Available BOP elements may vary, depending on the engine and application type.

- Engine Type Sheet 6

- Engine Type Sheet 6 US

- Engine Type Sheet 6 HH 2022

- Datacenter solutions for North America

Customer-only Resources

Get access to almost 2,000 Resources (such as Drawings, Service Technician Instructions, User Manuals, & more…) for Jenbacher Gas Engines with our dedicated Portal which includes advanced (yet easy to use!) search capabilities to find what you’re looking for.

Subscribe to our monthly Services Newsletter and additional materials to stay up-to-date with the latest Jenbacher technical news.

Type 6 Case studies

Our Services

Jenbacher Services

Bringing proven outcomes across the life cycle of your gas engines means less unplanned downtime, greater workforce efficiency, and lower operating costs. From commissioning to overhauling, our global network of qualified service experts provides the support you need, when you need it, by providing the latest technology.

Remote Monitoring & Optimization

Discover how partnering with digital technology can make your business life easier.

Jenbacher myPlant Performance Solution

Our cloudbased technology lets you manage your assets wherever you are, secure and live. Take control of the operating performance and profitability of your gas engine by giving it a digital life.